How Block Ice Machines Support Efficient Cooling and Cold Chain Industries

23 - 12 - 2025

Introduction: The Core Role of Block Ice Machine in Cooling and Cold Chain

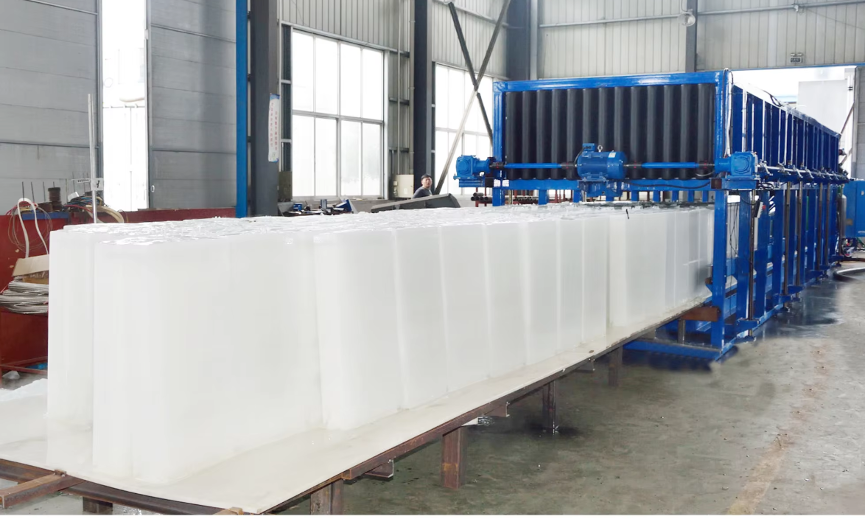

Efficient cooling and stable cold chain operation are the lifelines of industries such as food preservation, logistics transportation, and pharmaceutical storage. Among the key equipment driving these sectors, Block Ice Machine (also referred to as Ice Block Machine) stands out for its reliable ice production capacity and long-lasting cooling effect.

This article explores How block ice machines support efficient cooling, analyzes their core Block ice machine working principle, and showcases practical Block ice cooling solutions that empower cold chain industries.

Block Ice Machine Working Principle: The Foundation of Efficient Cooling

Key Mechanisms of Ice Block Machine for Stable Ice Production

The Block ice machine working principle is based on a cyclic refrigeration and ice-forming process that ensures continuous and efficient ice output. First, the refrigeration system compresses the refrigerant to form high-temperature and high-pressure gas, which releases heat and condenses into liquid through the condenser. The liquid refrigerant then expands rapidly via the expansion valve, absorbing a large amount of heat in the evaporator to lower the temperature of the ice mold area.

Clean water is pumped into the low-temperature ice molds, where it gradually freezes into solid block ice under the cooling effect. Once the ice reaches the preset thickness, the machine initiates the ice-harvesting process—hot gas is introduced into the evaporator to slightly melt the ice’s surface in contact with the mold, allowing the block ice to fall off smoothly. This automated cycle ensures the Block Ice Machine maintains a steady supply of block ice, laying the foundation for efficient cooling.

How Block Ice Machines Support Efficient Cooling: Core Advantages and Solutions

Block Ice Cooling Solutions for Diverse Efficient Cooling Needs

One of the key reasons Block Ice Machine excels in supporting efficient cooling is its ability to provide tailored ice cooling solutions. Block ice, with its large volume and slow melting rate, delivers long-duration cooling—far superior to small ice cubes in scenarios requiring prolonged low temperatures. For example, in long-haul refrigerated transportation, block ice placed in insulated containers maintains a stable low-temperature environment for 24-72 hours, reducing energy consumption compared to electric refrigeration systems.

Additionally, Ice Block Machine can be customized to produce different sizes of block ice (from 10kg to 100kg), adapting to varied cooling demands. Whether for small-scale seafood stalls or large-scale pharmaceutical cold storage, the flexible ice production of Block Ice Machine ensures targeted and efficient cooling, avoiding waste of cooling resources.

Empowering Cold Chain Industries: Practical Applications of Block Ice Machine

Food Cold Chain: Preserving Freshness from Production to Consumption

In the food cold chain, Block Ice Machine plays a critical role in preserving freshness. During the transportation of fruits, vegetables, and seafood, Block ice cooling solutions prevent spoilage caused by temperature fluctuations. For coastal fishing industries, large-scaleIce Block Machines produce massive block ice daily, which is immediately loaded onto fishing boats to keep catches fresh during long sea voyages.

Pharmaceutical and Special Cold Chain: Ensuring Temperature Stability

For pharmaceutical products requiring strict temperature control (such as vaccines and biologics), Block Ice Machine provides reliable cooling support. The stable low temperature maintained by block ice ensures that these products meet quality standards during transportation and storage. Moreover, block ice’s non-toxic and pollution-free properties make it suitable for direct contact with sensitive goods, enhancing the safety of cold chain operations.

FAQs About Block Ice Machines

Q1: What industries commonly use block ice machines?

A: Block ice machines are widely used in seafood processing, cold chain logistics, food preservation, concrete cooling, fisheries, and remote transportation where long-lasting cooling is required.

Q2: Why does block ice melt slower than other types of ice?

A: Block ice has a larger size and lower surface-area-to-volume ratio, which significantly slows melting and provides longer cooling duration compared to flake or crushed ice.

Conclusion

Block Ice Machine and Ice Block Maker are indispensable pillars of efficient cooling and cold chain industries. Their scientific working principle ensures stable ice production, while diverse ice cooling solutions address the unique needs of different sectors. As the cold chain industry continues to develop, Focusun's Block Ice Machine will further evolve with more energy-efficient and intelligent features, continuing to drive the efficiency and reliability of global cooling and cold chain systems. We sincerely welcome you to reach out to us for your ice making needs. Focusun's work is going to meet your every expection.

Location

Location