The Relationship Between Ice Thickness and Freezing Time in Block Ice Machines

14 - 11 - 2025

In the world of block ice production, two technologies have long defined the craft: the enduring brine cooling method and the newer, more efficient direct cooling approach.The connection between ice thickness and freezing time isn’t just a technical detail—it’s the backbone of production efficiency, energy usage, and ice quality. Grasping how these two factors interact lets operators fine-tune their production cycles, ensuring consistent performance for critical industrial needs like preserving fresh fish, cooling concrete, and keeping food supplies safe.

Basic Working Principle of Block Ice Makers

Brine block ice machines turn fresh water into substantial ice blocks through a traditional method: harnessing brine—plain saltwater—as their indirect cooling agent. The system’s backbone hinges on three essential components: a robust refrigeration unit, a spacious brine tank, and durable ice cans loaded with fresh water. Once up and running, refrigerant courses through evaporator coils nested inside the brine tank, driving the solution’s temperature down to a bitter –10°C to –15°C. That frigid brine then circulates around the ice cans, pulling heat away from the water trapped inside. Over the span of several hours, the water freezes slowly but steadily—starting at the outer edges, then inching its way toward the center—until it solidifies into ice blocks that are crystal-clear and rock-hard through and through.

Once freezing is complete, the ice cans are lifted from the tank and dipped briefly in warm water to release the blocks. This indirect freezing process delivers uniform cooling, top-tier ice quality, and reliable operation even when temperatures soar. Thanks to their durability and ability to crank out large volumes of ice, brine block ice machines are workhorses at fishing ports, seafood processing facilities, and industrial ice plants. They may not be as fast as direct cooling systems, but their dependability, easy maintenance, and suitability for non-stop production in tropical or coastal areas keep them in high demand.

Direct cooling systems, by contrast, take a more straightforward approach. They freeze water inside aluminum alloy molds that sit in direct contact with the evaporator surface. Refrigerant flows directly through coils welded to these molds, enabling rapid, efficient heat transfer from the water to the refrigerant.

With no salt brine or extra heat-exchange medium in the mix, cooling efficiency gets a significant boost, and the ice shines with superior clarity, hardness, and purity. But here’s the catch: freezing happens layer by layer, starting from the outer surface and moving inward. The thicker the ice, the longer it takes for that freezing front to reach the core.

Relationship Between Thickness and Freezing Time

Ice thickness (T) and freezing time (t) don’t follow a simple straight line—their relationship is roughly quadratic. In plain terms, as ice thickness goes up, freezing time skyrockets disproportionately. Heat transfer theory explains why this happens:

- Early in the freezing process, heat moves efficiently between the water and the cold surface. The temperature difference is sharp, and the ice layer is thin, so heat escapes quickly.

- As the ice layer thickens, it acts like a thermal blanket, slowing down the transfer of heat from the remaining unfrozen water to the refrigerant.

- Before long, the freezing front creeps toward the center at a snail’s pace, dragging out the total freezing time dramatically.

In practical terms, doubling the ice thickness can mean 3 to 4 times more freezing time. For example:

- A 10 cm thick ice block might take around 6 hours to freeze solid.

- Under the same refrigeration conditions, a 20 cm thick block could need 18–20 hours or more.

This exponential increase stems from the dropping heat transfer coefficient as the ice layer grows.

What Shapes the Thickness-Time Dynamic

Several key factors influence how quickly ice of a given thickness forms:

- Evaporating Temperature and Refrigerant Flow

Lower evaporating temperatures widen the temperature gap, speeding up heat removal and cutting down freezing time. But push the temperature too low, and you’ll hurt system efficiency and put extra strain on the compressor.

- Mold Conductivity

The material and thickness of the ice mold play a big role in freezing speed. High-conductivity aluminum molds transfer heat like a charm, enabling faster freezing with the same energy input. Brine block ice machines, however, use galvanized or sus304 ice cans—materials that don’t conduct heat as well as aluminum. That’s a big reason direct cooling machines have grown more popular in the ice business: they deliver better profits by way of faster production.

- Water Temperature and Purity

Warm inlet water or water with high mineral content slows down freezing and can leave ice looking cloudy or feeling soft. Clean, cool water is key to quick freezing and high-quality ice.

- Defrost Cycle and Operating Efficiency

The defrosting system’s performance also leaves an indirect mark on production cycles. Frequent or incomplete defrosting robs the system of cooling capacity for the next batch, throwing off timelines.

- Finding the Appropriate Ice Thickness

In real-world operations, producers walk a tightrope between ice size and production speed. Thicker ice blocks are sturdier and melt more slowly, but overly long freezing times eat into productivity and drive-up electricity bills.

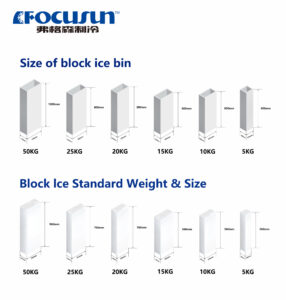

For most commercial direct cooling block ice machines, the sweet spot lies between 100–160 mm (10–16 cm). For brine-type machines, it’s 120–250 mm (12–25 cm). Within these ranges, the ice is tough enough to handle transport and handling, while freezing times stay reasonable—6–10 hours, depending on ambient conditions and refrigerant performance.

When customers need thicker ice, it’s often smarter to add more molds or use parallel freezing systems than to stretch out the freezing time for a single block.

Focusun’s Edge in Ice-Making Tech

As a global leader in industrial ice-making solutions, Focusun Refrigeration has mastered this balance through cutting-edge system design. The company offers both brine cooling (also called saltwater) and direct cooling block ice machines, each tailored to different needs.

Focusun’s smart control systems shine during the final freezing phase, where heat transfer naturally slows to a crawl. These systems minimize energy waste, ensuring each batch hits the desired thickness without over-freezing or wasting power. The result? Focusun’s machines slash freezing times by 15–20% compared to conventional designs, all while delivering ice with uniform thickness and crystal-clear quality.

In conclusion, the relationship between ice thickness and freezing time boils down to thermal resistance and energy transfer efficiency. The thicker the ice, the slower heat escapes, and the more dramatically freezing time stretches. By optimizing ice thickness to match operational needs—paired with advanced control systems like Focusun’s—producers strike the perfect balance between production efficiency, energy use, and ice quality.

Location

Location