Why Containerized Block Ice Machines Are Actually Perfect for Emergency Ice Source Solution

25 - 12 - 2025

Here's a problem I keep seeing across different industries: you need ice, and you need it fast. Mining camps in the middle of nowhere. Remote fishing operations. Disaster response situations. Big temporary events. The usual answer - build an ice plant - just doesn't work when you're dealing with these scenarios.

Two things always come up. First, there's no infrastructure and definitely no time to build something permanent. Second, traditional ice-making equipment? It's a pain to move, it's complicated to set up, and if your project only runs for a few months or you need to relocate, you're basically stuck.

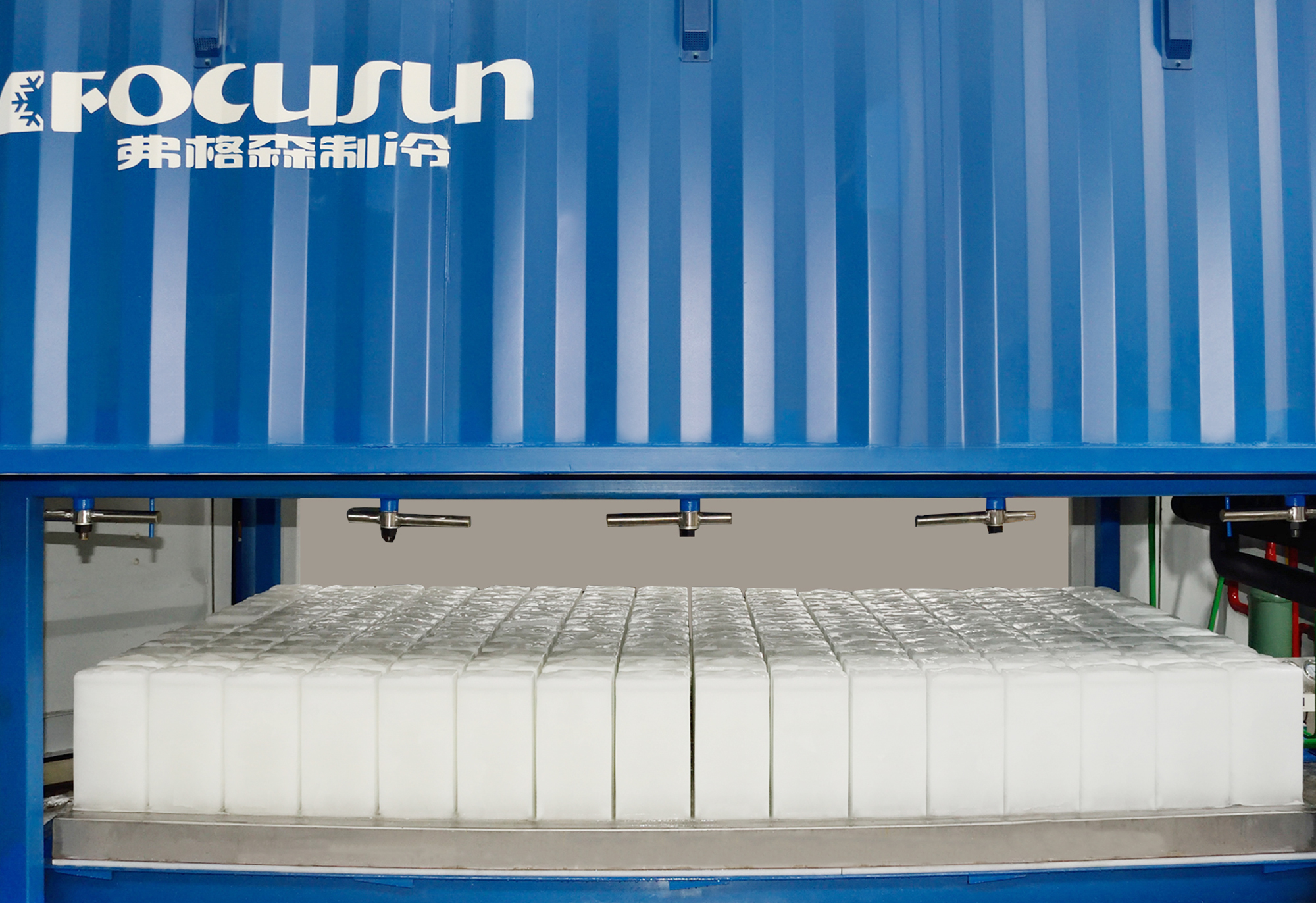

The emergence of the containerized block ice machine provides a completely new solution to this dilemma. It pre-integrates the complete ice-making system into a standard shipping container, achieving plug-and-play and rapid deployment of the "ice plant."

What Makes Containerized Block Ice Machine Different?

The containerized approach basically puts the entire ice-making system inside a standard shipping container. Everything's pre-integrated. You can literally just ship it, hook it up, and start making ice.

1.Getting up and running fast

When the container shows up on site, you connect water and power, and you're producing ice. We're talking days, not months. No construction crews, no civil engineering, no complicated installation process. That timeline difference is massive when you're dealing with emergency response or tight project schedules.

2.Built to handle rough conditions

These block ice maker uses reinforced ISO standard containers - same ones that cross oceans on cargo ships. They're weatherproof, dustproof, handle corrosion. There's internal lighting and drainage already set up. We've seen them running in ports, mining sites, all kinds of challenging environments, and they hold up.

3.Keeps costs manageable over time

Because everything's pre-integrated - piping, electrical, the whole containerized block ice machine system - there's less that can go wrong during setup. The corrugated aluminum flooring holds up well. The whole design is meant to reduce how much you need specialized maintenance people, which adds up to real savings if you're operating this thing for a while.

Picking the Right Type of Containerized Block Ice Machine for Your Situation

Custom containerized block ice machines can go two ways - direct refrigeration or brine systems. Each has its place.

1.Direct cooling containerized machine

Everything's compact, fits inside the container. Works really well for small to medium operations where you need something that's super easy to install, space is tight, and you want to start producing quickly. Generally simpler to operate too.

2.Brine-based containerized machine

These brine containerized machine integrate the bigger components - brine tanks, evaporators - into a heavy-duty container. You get the traditional brine advantages (higher capacity, very stable operation) but now it's mobile. Makes sense for larger-scale projects where you might need to relocate but still want serious ice production capacity.

Common Questions People Ask

Q1.Is the ice clean enough for food applications?

The direct cooling versions don't use brine at all - just produces clean ice that meets food-grade standards. Works fine for seafood, meat processing, any food cold chain application.

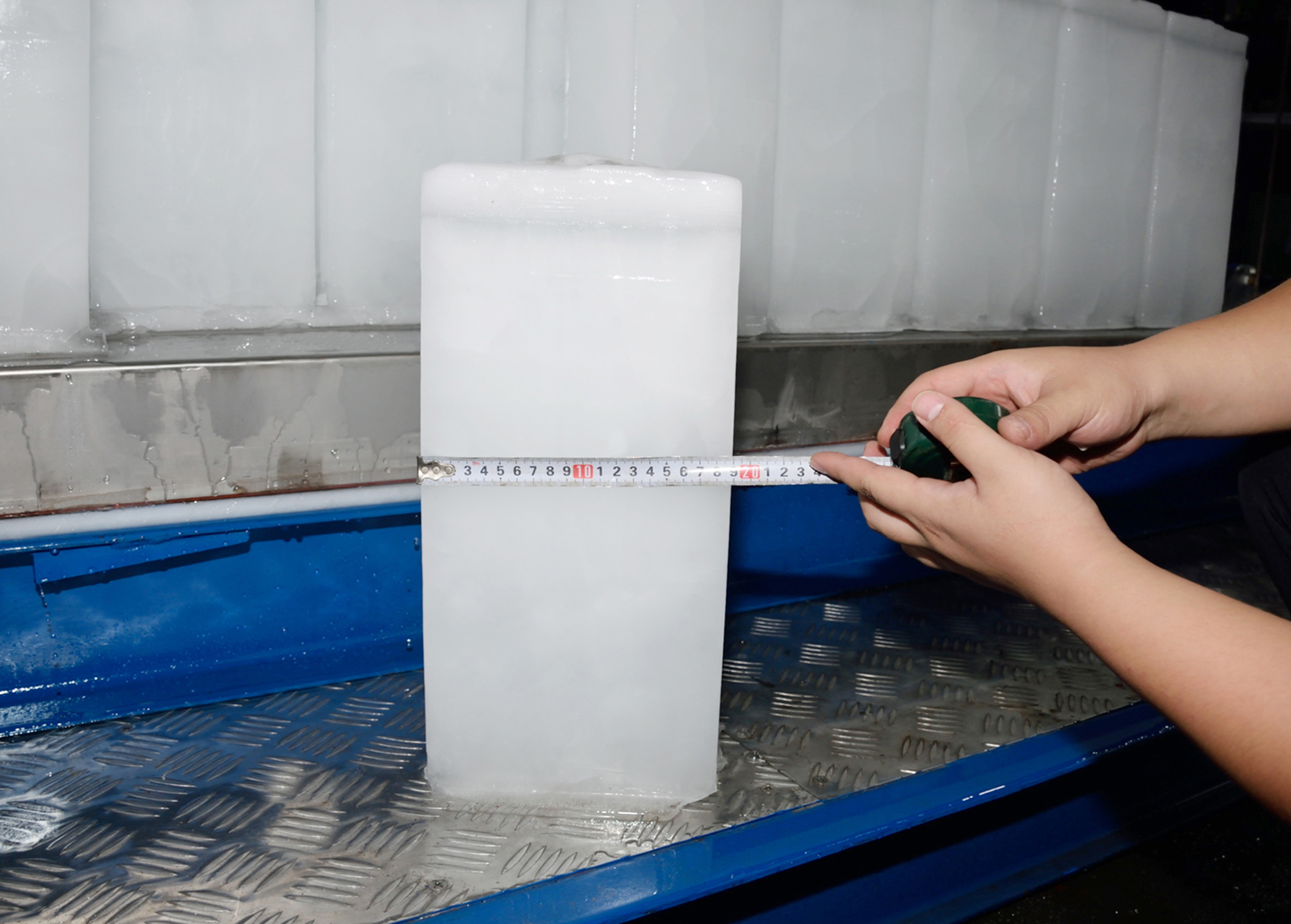

Q2.Can you adjust the ice block sizes?

Yeah, there's flexibility there. Common sizes are 5kg, 10kg, 25kg blocks. Production capacity can range from about 1 ton up to 20 tons per day depending on what you need and which model you go with.

Q3.What's the max capacity these can handle?

For the 20-foot container models (20GP), direct cooling tops out around 5 tons per day. The larger 40-foot high cube containers (40HQ) can do up to 20 tons daily. Brine systems can push even higher if needed.

Q4.Where does this make the most sense?

Ports and docks, seafood processing, food cold chain operations, commercial ice supply. Also great for remote construction sites or any situation where you need decent capacity but also need to deploy quickly or maybe move the whole operation later.

Conclusion: Choosing a More Reliable and Flexible Ice-Making Solution (Containerized Block Ice Machine)

The containerized block ice machine isn't some breakthrough refrigeration technology - it's more about rethinking how you package and deliver ice-making capability. Instead of building a fixed facility, you're getting a mobile ice source that can be transported and deployed wherever you need it.

For projects with short timelines, remote locations, or situations where you might need to move or scale up later, having that kind of flexibility is huge. You're not locked into a permanent installation that might not make sense long-term.

It's basically the shift from "we're building an ice plant here" to "we're bringing ice production capacity to wherever we need it."

If your operation is constrained by infrastructure challenges, tight construction windows, or you just need flexible capacity that can potentially relocate - the containerized route gives you way more control.

Focusun has been a containerized block ice machine supplier for a while now, and their industrial refrigeration systems are holding up well in challenging environments worldwide. If you're evaluating options, they can walk you through what would actually work for your specific capacity needs and site conditions.

Contact us for customized solutions based on your production requirements and site constraints.

Location

Location