Why Plate Ice Machines Actually Work Better for Large-Scale Cooling?

26 - 12 - 2025

Here's a problem I keep running into with different industries - seafood processing, big food factories, concrete plants, all of them. They need serious amounts of cooling, and the typical ice options just don't quite work right.

You've got crushed ice, which melts too fast and you're losing cold capacity during storage. Flake ice cools quickly, sure, but try storing it for any length of time and you'll see the problem. What most operations really need is something that balances fast production, long storage life, and can actually make gentle contact with products without causing damage.

The operating costs add up when you're constantly replacing melted ice, and product quality suffers when your cooling media isn't quite right for the job.

Why Focusun's Approach Is Different

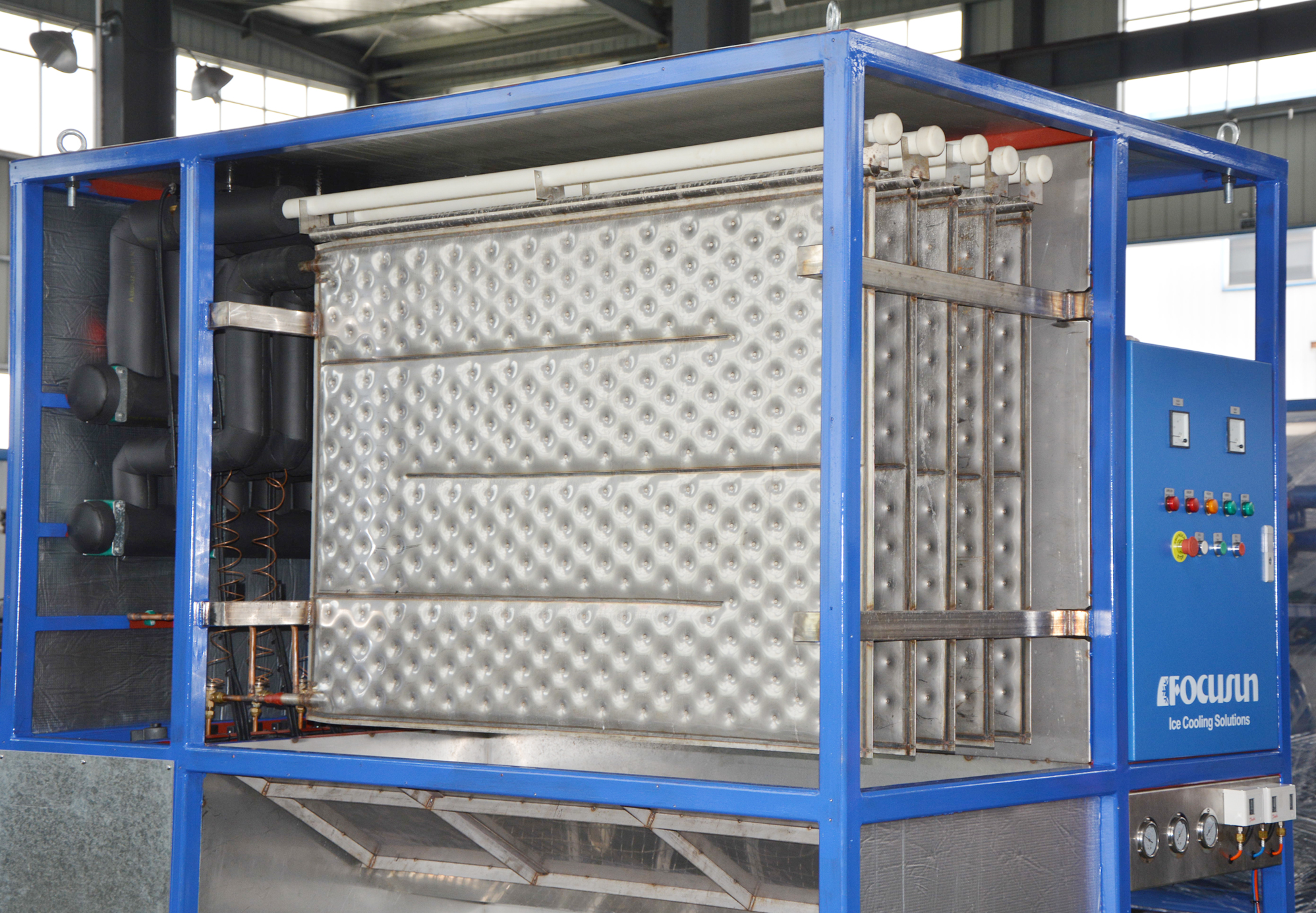

The plate ice machine that Focusun builds (based on German technology) addresses this pretty directly. It's not just about making ice - it's designed around how ice actually gets used in large-scale operations: batch cooling, long-term cold chain storage, that whole process.

What's Actually Different About Focusun Plate Ice Machine?

1.Plate Ice Lasts Way Longer

You can adjust the plate thickness anywhere from 10 to 15 millimeters depending on what you need. Compared to flake ice, each piece has more mass and a denser structure, which means it melts slower. Sometimes significantly slower.

This matters a lot for fishing operations during high season when you need to pre-store large quantities of ice, or for long-haul cold chain transport where the ice needs to maintain temperature for extended periods. Less melting means less spoilage risk and you're not constantly replenishing ice.

2.De-icing System Is Actually Clever

The industrial plate ice machine uses thermal fluoride de-icing technology - fully automated. The evaporator core uses 304 stainless steel and aluminum alloy, welded with some pretty advanced techniques. Heat exchange efficiency is really high.

But here's the smart part: during de-icing, the system uses hot refrigerant gas from the compressor itself. Just redirects it into the evaporator. No separate electric heating, no steam system. The whole de-icing cycle runs about 120 seconds, which keeps the production process continuous. Energy-efficient and fast.

Plus the food-grade materials and smooth surfaces hold up well in demanding environments and meet hygiene requirements.

3.Built For Reliability In Tough Conditions

Industrial environments are rough on equipment. Focusun uses top-tier components - Bitzer compressors from Germany, Danfoss control valves from Denmark, Siemens PLC systems. That component selection matters for 24/7 operation.

There's also a closed-loop water circulation system that keeps things running stable even in challenging conditions - high dust, high humidity, concrete plants, large seafood processing facilities, whatever. The plate ice machine needs to just work, day after day.

Different Scales for Different Operations

1.Large Industrial Plate Ice Machine

These are modular setups designed for serious production volume. Seafood processing centers, large chemical plants - anywhere you need massive ice capacity as part of your core infrastructure.

2.Small Commercial Plate Ice Machine

More compact design. Works well for big restaurants, central kitchens, regional distribution centers. Small commercial plate ice machine still gives you stable, food-safe plate ice for bulk cooling and food handling, just at a smaller scale.

Common Questions

Q1.What kind of production capacity are we talking about?

You can configure different ice sizes - 5kg, 10kg, 25kg blocks. Daily capacity ranges from about 1 ton up to 32 tons depending on the setup.

Q2.Is it actually food-safe?

Yeah. Focusun has this water purification tech they call "Pre-Purify" - handles source water treatment before ice production. The plate ice can make direct contact with food products.

Q3.Does plate ice machine work for construction applications?

Definitely. Concrete cooling in hot climates is a major use case. Also fisheries, food processing, chemical industry, large refrigeration systems. The uniform shape makes it easier to store and handle compared to other ice types.

Q4.Can you customize the setup?

Yes, different capacities, either fixed installations or modular systems depending on what you need.

Conclusion: Choose A High-efficiency And Long-lasting Bulk Cooling Solution-Plate Ice Machine

Focusun industrial plate ice machine has longer storage life. Which means you're using less ice overall. The efficient de-icing keeps production continuous. Industrial-grade components mean less unexpected downtime, which in large-scale operations adds up fast.The plate format itself - stackable, good air circulation, sustained cooling - helps optimize warehouse and logistics efficiency. You're basically treating ice as a strategic asset for your operation rather than just a consumable that melts away.

Whether you're managing a marine ice plant with major storage requirements, or a food processing line that needs consistent cooling day in and day out, Focusun's got options from commercial-grade up to full industrial scale. As a professional plate ice machine supplier , we offers ice machine solutions across different capacity ranges to match your operational needs.

Location

Location