How to Choose The Right Ice Packaging Machine?

23 - 1 - 2026

Running an ice plant, managing a supermarket distribution center, or supplying branded ice products? Then you already know the packaging headache. You've got all this bulk ice that needs to become neat, retail-ready packages. Try doing that manually and you'll quickly see the problems: its slow, messy, weights are inconsistent, seals leak, and there's always the contamination risk. None of that scream 'professional product.' Moving from just making ice to actually selling a product people want to buy—that's where packaging automation makes all the difference.

Choosing an ice packaging machine that suits your business needs can not only significantly improve packaging efficiency but also represents a strategic investment in the brand image, hygiene, safety, and market competitiveness of your end products. The following key dimensions will help guide you in making an informed decision.

Step One: Match the Machine to Your Operation Size

The choice of an ice packaging machine primarily depends on your production volume, investment budget, and level of automation required.

1. Fully Automatic Ice Packaging Machine: For High-Volume, Non-Stop Operations

Who needs this: Large ice plants, suppliers serving chain supermarkets with constant demand, anyone processing massive quantities of bulk ice daily. If you're handling cube ice, tube ice, flake ice—whatever the type—at scale, this is your category.

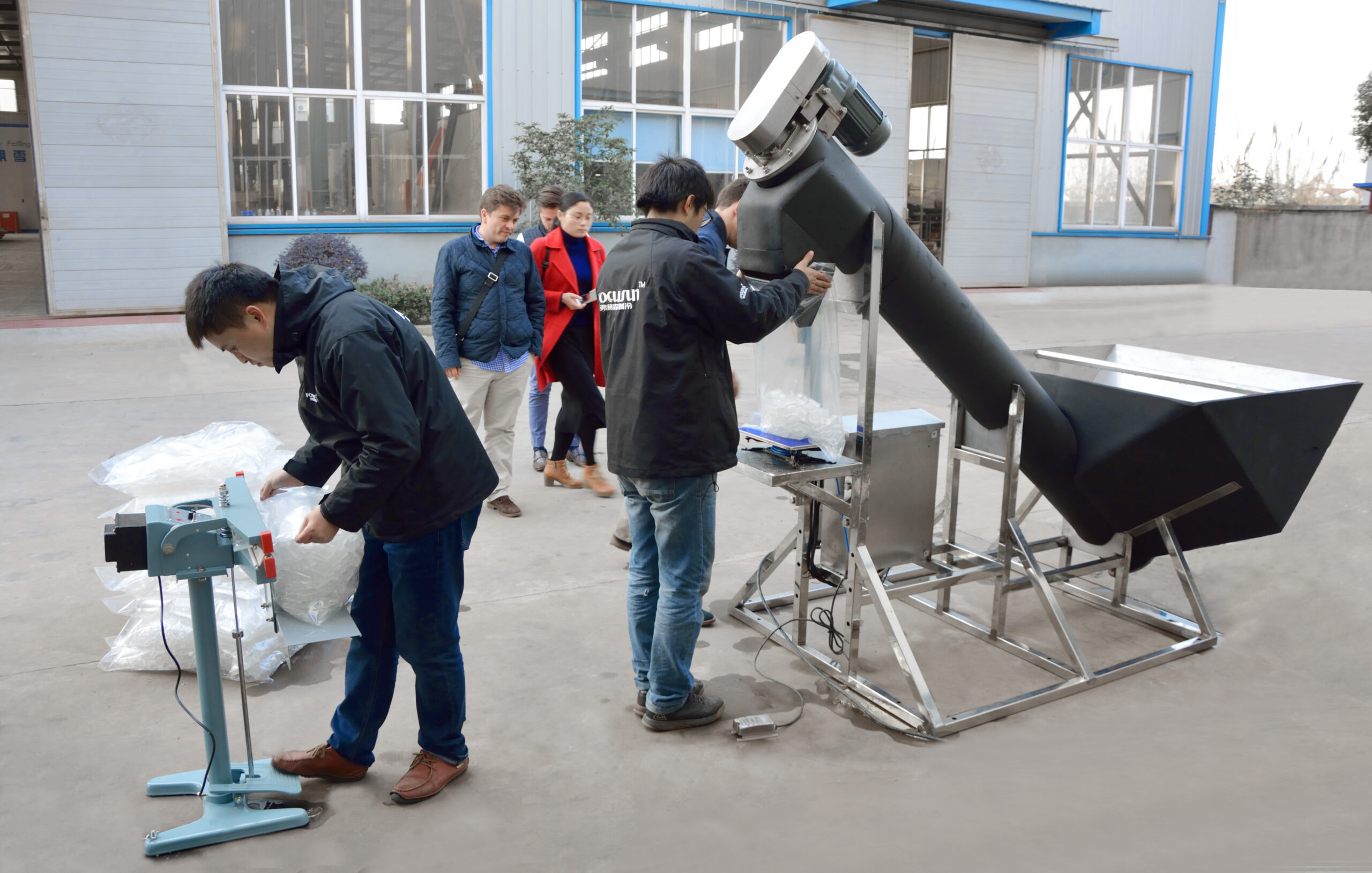

What it does: Take Focusun's fully automatic ice packaging machine as an example.

It handles everything from ice feeding through sealing without anyone touching it. The speed? We're talking 25-40 bags per minute depending on bag size and ice type. That kind of throughput eliminates bottlenecks completely. The entire machine is built from food-grade 304 stainless steel, which means it's built to last, easy to keep clean, and meets strict food safety requirements. You've got a touchscreen panel that makes setting parameters and monitoring production straightforward. It can be used with ice-making equipment such as tube ice machines and flake ice machines. Plus, it adapts easily to different ice types, so you're covered whether you're packaging multiple product lines or switching things up.

2. Semi-Automatic Ice Packaging Machine: The Smart Middle Ground

Who needs this: Smaller ice rinks, regional distributors, catering central kitchens—operations where manual packaging isn't cutting it anymore, but you're not quite at industrial scale. You need better efficiency and hygiene control without the full automation price tag.

What it does: Focusun's semi-automatic ice packaging machine strikes a good balance. You place the bags manually, then the machine handles the weighing and filling automatically. That's the time-consuming part sorted, but you still have flexibility for different specifications and small batch runs. The built-in precision weighing system keeps every bag consistent—no more guessing. It's compact, made with corrosion-resistant stainless steel, meets food-grade standards, and handles everything from 5kg bags to 10kg to custom sizes. For small to medium businesses trying to standardize their product and build a brand, this is the cost-effective route.

Step Two: Focus on Core Performance and Hygiene Standards

Once you've narrowed down the type, dig into these performance specs. They determine whether the machine will work for your specific situation.

(a)Compatibility and Flexibility: Assess whether the ice packaging machine can handle the ice types you produce (cube ice, tube ice, crushed ice, etc.). Also check how easy it is to switch between different package sizes or materials (PE bags, composite film bags, etc.).

(b)Packaging Speed and Capacity: Evaluate based on your peak production demands. Equipment capacity is usually measured in "bags per minute" or "tons per hour" (e.g., Focusun ice packaging machine can process 3 to 5 tons of ice per hour). Choose a model with some capacity headroom to accommodate business growth.

(c)Weighing Accuracy: This directly affects your costs and customer trust. If bag weights are all over the place, you're either giving away product or annoying customers. Quality machines use high-precision sensors and stable control systems. That consistency matters.

(d)Materials and Hygiene: Anything touching the ice needs to be food-grade stainless steel—304 is standard. This ensures no weird odors, resists corrosion, cleans easily, and meets food safety standards like HACCP. Don't compromise here. Contamination issues will destroy your reputation fast.

Step Three: Evaluate Supplier Expertise and Support Services

Choosing a reliable ice packaging machine supplier is crucial. A professional supplier should not only provide high-quality equipment but also possess:

(a)Technical Support and Training: Offer comprehensive installation, operation, and maintenance training, along with prompt technical response.

(b)After-Sales Service: Ensure quick repair and spare parts support throughout the equipment's lifecycle.

(c)Customization Capability: Can they adapt to your specific process or packaging needs? Every operation is a bit different. A supplier that can customize solutions shows they actually understand the industry.

Frequently Asked Questions(FAQ)

Q1.What scenarios are ice package machines suitable for?

This machine is ideal for ice plants, supermarkets, seafood processing, and cold chain logistics, where fast and reliable ice packing is required.

Q2. What kind of performance can I expect?

Depends on bag size and ice type, but typically 3 to 5 tons of ice per hour. That's a substantial throughput for most operations.

Q3. Can I get custom modifications?

Yes. Focusun has technical and after-sales teams with years of refrigeration industry experience. They'll work with you to build the right solution for your specific needs.

Conclusion: From Purchasing Equipment to Value Investing

A commercial ice packaging machine is not just a packaging device, but a comprehensive end-product solution integrating conveying, metering, bag making, filling, sealing, and coding. Choosing the right ice packaging machine is a systematic decision-making process that requires a comprehensive balance of production scale, automation level, performance parameters, hygiene standards, scenario adaptability, and supplier strength.

As a professional China ice packaging machine supplier, we help customers transform bulk ice products into standardized, branded, and high-value-added goods, enabling them to build a solid quality barrier and efficiency advantage in the fierce market competition.

Location

Location