How Does The Focusun Plate Ice Machine Work Efficiently?

23 - 1 - 2026

Large-scale food processing has a particular problem with ice. You need tons of it. Literally. But here's the catch—you don't always need it the exact moment you make it. Sometimes you're building up reserves for peak season. Sometimes you're stockpiling during low-demand periods to handle upcoming surges. Crushed ice doesn't work for this. Melts too fast. You'd lose half of it to melt water before you even use it.

Plate ice machines from companies like Focusun solve this specific problem. Not by accident. By deliberate engineering focused on applications where storage life matters as much as cooling power. Understanding how these machines work explains why they've become standard equipment in operations most people never see.

What's the Secret to the High Efficiency of a Plate Ice Machine?

The efficiency of the Focusun plate ice machine stems from its precise "plate evaporation" and "hot-gas de-icing" cycle:

Ice Making Phase: Purified water is evenly sprayed onto the surface of low-temperature metal plates (evaporator) arranged vertically or at an incline, rapidly freezing into plate ice of predetermined thickness.

De-icing Phase: Once the ice layer reaches the set thickness, the control system switches valves to introduce high-temperature, high-pressure refrigerant gas (hot gas) into the internal channels of the evaporator plates.

Separation and Collection: The hot gas causes instantaneous slight melting at the contact surface between the ice plate and the plates. The entire ice plate detaches completely under gravity or with auxiliary mechanisms, entering the ice storage bin or conveyor belt. The system then automatically switches back to refrigeration mode to begin the next cycle.

Unique Advantages of Focusun Plate Ice Machine

The Focusun plate ice machine directly tackles the above pain points through systematic innovation in materials, processes, and control. Its efficient operation is manifested in the following three aspects:

1. Long-Term Storage Efficiency

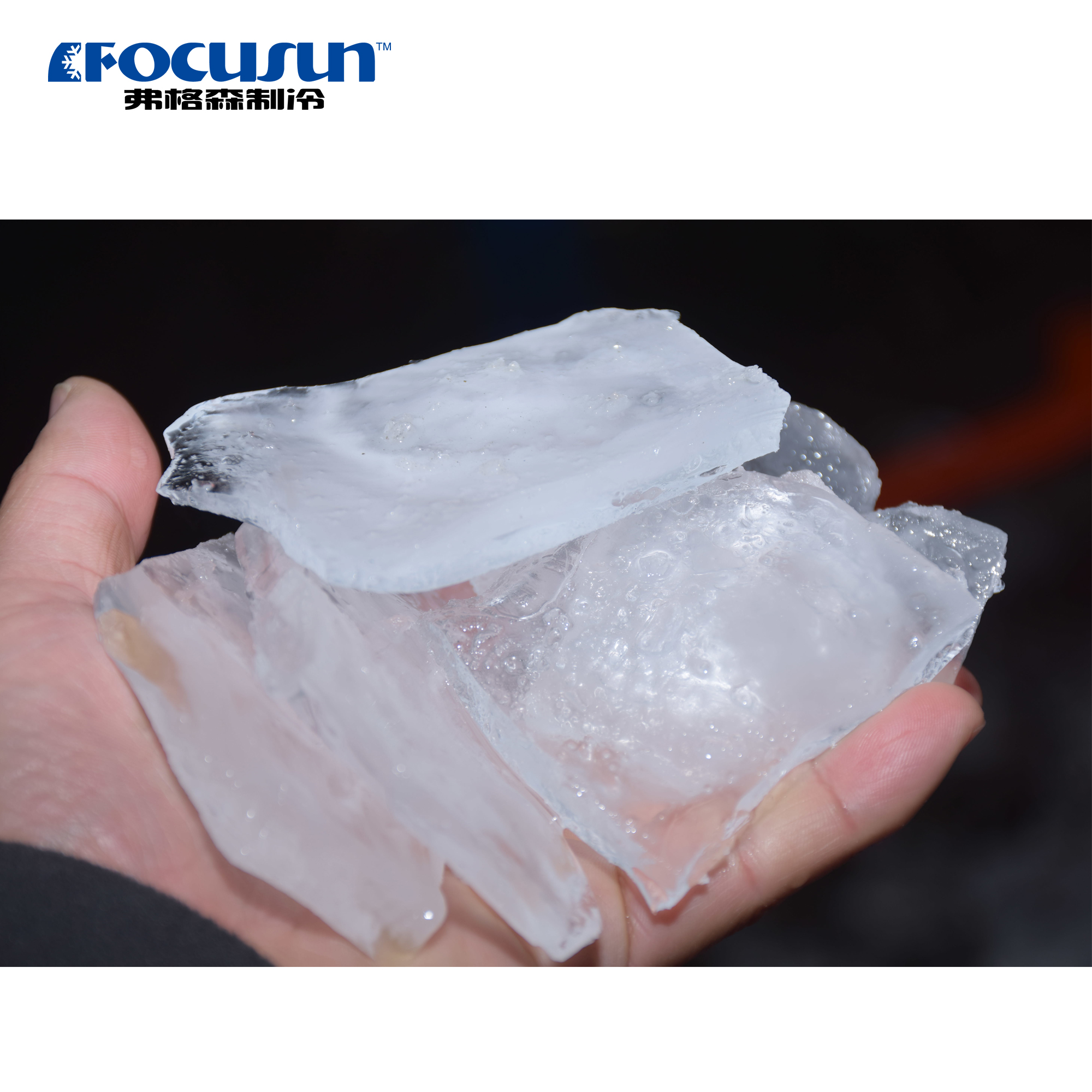

The ice produced by the plate ice machine is in the form of uniformly thick plates (typically 10-15 mm, adjustable). Compared to loose flake ice, its structure is denser, with higher cooling capacity per unit volume, and gaps exist when stacked, providing good air permeability. This significantly slows the melting rate of plate ice and greatly extends its storage period. It is particularly suitable for large-scale strategic ice storage during fishing seasons or peak production periods.

2. Achieving "120-Second Rapid De-icing"

Hot-gas de-icing uses waste heat that exists anyway in the refrigeration cycle. The compressor produces hot gas as part of normal operation. Instead of just dumping that heat in the condenser, you harvest it briefly for de-icing. Clever use of energy already in the system. Speed improves dramatically. Complete de-icing in 120 seconds typical. Compare that to mechanical systems taking five or ten minutes. Faster cycling means higher effective production capacity from the same evaporator surface area. More ice per day from given equipment size. This technology not only offers fast de-icing speed and extremely low energy consumption but also avoids equipment wear caused by thermal stress, ensuring stable production capacity under continuous high loads.

3. Industrial-Grade Reliability and Gentle Cooling

The industrial plate ice machine integrates top-tier global industrial components, such as a Bitzer compressor from Germany, Danfoss control valves from Denmark, and a Siemens PLC control system, ensuring long-term reliable operation in high-humidity, highly corrosive environments like seafood processing plants. The produced plate ice has rounded edges and uniform texture. When used for covering or mixing with seafood (e.g., whole boxes of fish, shrimp), it enables large-area, uniform, and gentle heat dissipation, preventing localized frost damage or physical injury, perfectly preserving product form and freshness.

Common Questions About Focusun Plate Ice Machine

Q1:What is the production capacity?

Production capacities (ranging from 1 ton to 32 tons per day) according to your needs.

Q2.Does the equipment support customization?

Absolutely. We offer two models: small commercial plate ice machine and large industrial plate ice machine. Small commercial plate ice machines are suitable for large restaurant central kitchens and regional distribution centers. Large industrial plate ice machines are ideal for seafood processing centers and large chemical plants building core ice source infrastructure.

Q3.How durable is the equipment?

The Focusun industrial plate ice machine has a long service life and is equipped with components from reliable international parts suppliers. Such as Bitzer compressors, Danfoss valves, and Siemens PLC controllers.

Conclusion: Choose an Efficient Ice-making Solution for Food Processing

For the food and seafood processing industry, the Focusun plate ice machine is not merely an ice-making device but a large-scale cooling solution centered on long-term storage, efficient de-icing, and industrial-grade reliability. By providing plate ice that is easy to stockpile, slow to melt, and cools uniformly, it directly helps businesses optimize warehousing and logistics, reduce overall ice usage costs, and ensure the continuous and stable operation of production lines.

As an experienced plate ice machine supplier, Focusun offers professional cooling solutions ranging from commercial to industrial grades, becoming a reliable cooling backbone for your large-scale operations.

Location

Location