Why Cold Chain Logistics Relies on Ice Maker Ice Machine

6 - 1 - 2026

The global cold chain logistics sector is on a steady growth trajectory, and the driving force behind this expansion is clear: surging demand for fresh produce, temperature-sensitive pharmaceuticals, and a host of other goods that rely on unwavering thermal control to stay viable.

After all, maintaining a consistent low temperature from the moment products leave the production line to the second they reach their final destination isn’t just a best practice—it’s the cornerstone of preserving product quality, a factor that simply cannot be compromised in today’s competitive market.

Key Cold Chain Challenges Solved by Ice Maker Ice Machine

Temperature Swings During Long-Distance Shipping

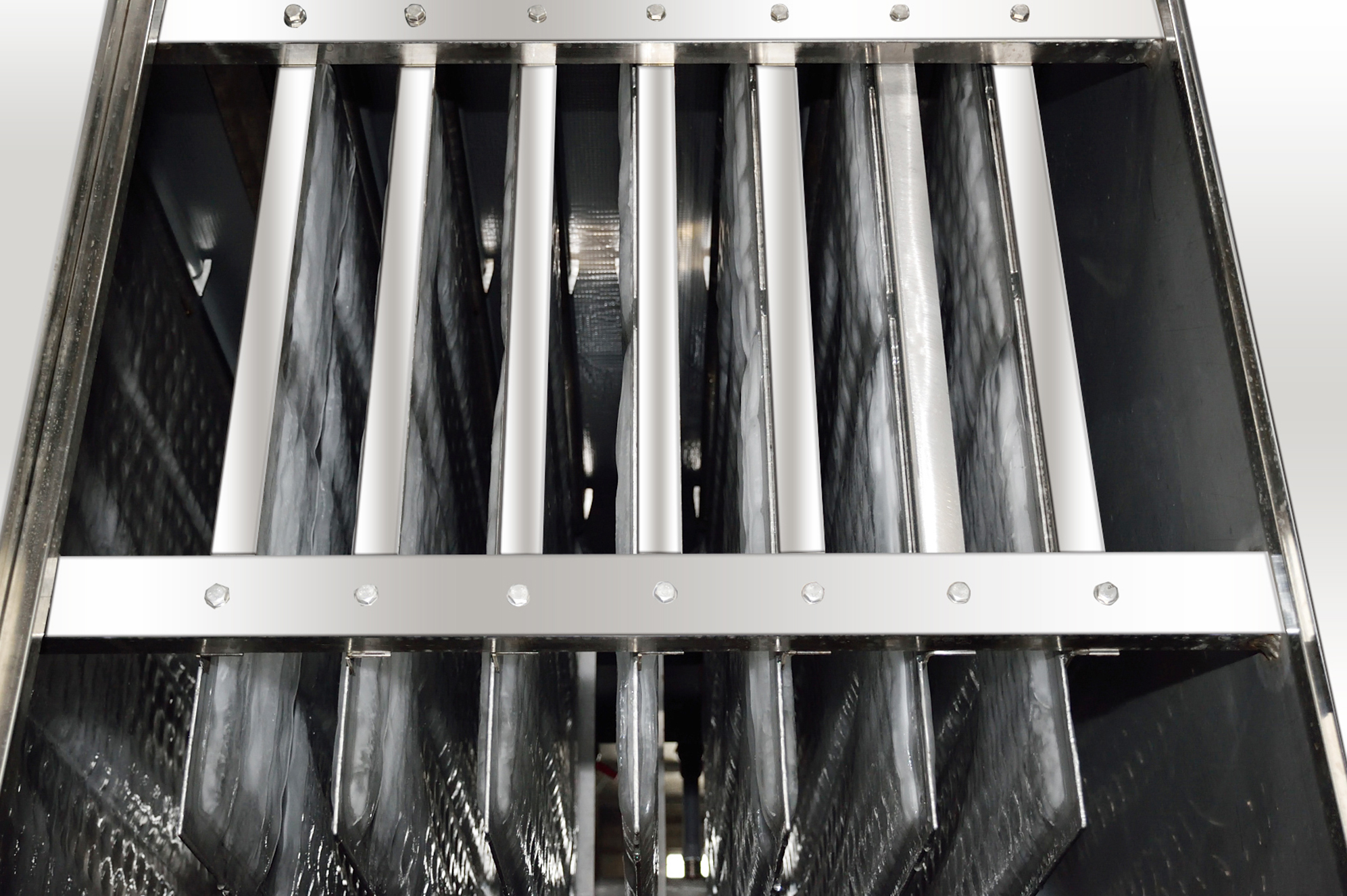

Long-distance shipping is a make-or-break part of the cold chain. Temperature changes along the way often lead to products going bad, which is a major loss for businesses. Dry ice, a common cooling choice in the past, has its downsides: it doesn’t stay cold for long, and the carbon dioxide it releases as it melts can be a safety risk. On the other hand, an ice maker ice machine—especially professional models from a trusted commercial ice machine maker—can keep producing ice during the trip. Take Focusun’s plate ice machine, for example. It makes high-quality ice plate that has a large surface area and cools quickly, keeping refrigerated trucks at a steady low temperature for hours on end. This cuts down on product waste significantly.

Fast Cooling Needs for Fresh Product Pre-cooling

Fresh fruits, vegetables, and seafood have an urgent cooling need the second they’re harvested or processed. Drag your feet on this step, and bacteria will multiply at breakneck speed, turning crisp produce limp and fresh seafood off in no time flat.

For cold chain operators, this means efficient icing isn’t just a nice-to-have—it’s a top priority that directly impacts product quality and profitability. A reliable ice maker rises to the occasion here, churning out massive volumes of ice in a short window to match the non-stop precooling demands of busy production lines.

And that’s where Focusun’s ice maker really shines. Equipped with an intelligent control system, it lets you tweak both ice output and ice shape to fit the unique precooling needs of different products—say, fine flake ice for delicate leafy greens or denser block ice for bulk seafood shipments. This level of precise control doesn’t just cool products down; it locks in their peak freshness for longer, extending shelf life and boosting market appeal.

Why Ice Maker Ice Machine Stands Out in Cold Chain Logistics

Compared to other cooling equipment, ice maker ice machine works better in the varied, often tricky scenarios of large scale cooling projects. It handles different environments well—whether it’s hot weather or remote areas—so the cold chain never breaks. It’s also energy-efficient and eco-friendly. Focusun’s ice maker ice machine uses advanced refrigeration tech that cuts down on energy use while still cooling effectively, avoiding the pollution that comes with dry ice production. Plus, the ice it makes is clean and hygienic, meeting the strict standards of the food and pharmaceutical industries.

FAQ: Ice Maker Ice Machine for Cold Chain Logistics

- What ice maker ice machine is best for seafood cold chain shipping?

A plate ice machine is your best bet. The ice plate it produces is tough and has a large surface area, which cools seafood quickly and keeps the temperature steady during shipping. Focusun’s plate ice machine is widely used in seafood cold chains because it’s reliable and lasts a long time.

- What should I look for when choosing a commercial ice machine maker for cold chain use?

Key things to consider are brand trustworthiness, how stable and reliable the products are, the quality of after-sales service, and whether they can customize equipment for your needs. As a professional commercial ice machine maker, Focusun has lots of experience with cold chain solutions. They can make equipment that’s tailored to your specific logistics setup.

- Can an ice maker ice machine meet the ultra-low temperature needs of pharmaceutical cold chains?

Yes, it can. Focusun’s specialized ice maker ice machine can work together with other refrigeration systems to reach the ultra-low temperatures needed for pharmaceutical cold chains. The ice it makes is non-toxic and meets the strict cleanliness standards required by the pharmaceutical industry.

- How do I maintain an ice maker ice machine for long-term cold chain use?

Basic maintenance steps include regularly cleaning the evaporator and water tank, and checking the refrigeration system and electrical parts periodically. Focusun offers a full after-sales service package—they provide professional maintenance advice and quick access to spare parts, so your equipment stays running smoothly and consistently.

- Is an ice maker ice machine a cost-effective choice for small and medium cold chain businesses?

Absolutely. Focusun has a wide range of ice maker ice machine models, so you can find one that fits the output needs of your small or medium business. These machines are energy-efficient and don’t cost much to maintain, which helps cut down on long-term operating costs.

Conclusion

As a foundational workhorse for reliable, efficient cold chain logistics, an ice maker isn’t just a piece of equipment—it’s a silent guardian of product quality that solves those nagging cooling pain points older methods simply can’t touch, like the inconsistent temperature control that once turned a shipment of fresh coastal shrimp mushy mid-transit or the uneven pre-cooling that left crates of leafy greens wilting before they reached the market. If your cold chain business is chasing tighter efficiency, slimmer product waste, and steadier quality standards, partnering with a trusted provider like Focusun isn’t just a smart move—it’s a game-changer that turns those goals into daily reality; whether you’re navigating the strict temperature demands of seafood shipping, the delicate pre-cooling needs of farm-fresh produce, or the precision-required logistics of pharmaceuticals, we craft customized ice maker solutions tailored exactly to your workflow, not a one-size-fits-all template.

Reach out to us today—our team doesn’t just deliver high-quality machines; we stand beside you with personalized technical support that keeps your cold chain humming smoothly, no matter what challenges come your way.

Location

Location