How to Select the Right Plate Ice Machine for High-Volume Industrial Cooling

3 - 2 - 2026

A reliable cooling source is key for keeping operations running. For many, the answer is not generic ice-making options but specialized industrial equipment made for endurance and efficiency. This is when the plate ice machine becomes a critical asset, built to meet the tough demands of continuous, large-scale production. This guide will explain why a plate ice maker is often the best choice for midstream industrial applications and how to pick the right one to protect your production line from cooling-related stops.

Why Reliable Industrial Cooling is a Make-or-Break Factor

In areas like ready-mix concrete production, exact temperature control is needed for getting the right curing strength and workability. The fisheries and food processing industry, maybe most importantly, depends on unbroken cold chain integrity from processing to transport; any break can cause spoilage and safety risks.

The shared problem in these fields is the need for a huge, steady, and reliable ice supply that can fit smoothly into automated processes and handle 24/7 running schedules. This is not just a small issue—it's a core production need. So, investing in a dedicated industrial plate ice maker is not an extra cost but a smart decision for quality assurance and operational growth. Its ability to provide high-volume, uniform ice directly affects your profits by protecting product quality and maximizing output.

Why Choose Focusun for Your Plate Ice Machine Solution

Unmatched Customization and Scalable Capacity

Focusun knows that industrial needs are never the same. Our plate ice plant options range from small units making 1 ton per day to large-scale systems providing up to 48 tons daily. Importantly, everything can be customized—ice plate size, thickness, and total output can be made to match your exact process needs. If you need a standard setup or a special solution like our project in Seychelles—where we built machines to make specific 25x25mm ice plates for a high-temperature place—Focusun has the technical skill to deliver.

Robust, Modular Design for Easy Deployment and Maintenance

Our machines are built for real use. The small-capacity plate ice factory units are compact, pre-built on steel frames for simple containerized shipping and fast installation—basically "plug and play." The large-capacity systems have a smart modular design, separating the power unit, evaporator module, and refrigeration system.

Superior Efficiency and Advanced Technology

Focusun focuses on sustainable performance. Our plate ice makers use advanced evaporator plates made from clean SUS304 stainless steel and aluminum alloy. The new technology allows quick ice formation and an efficient defrost cycle (as fast as 120 seconds using a combined water and hot gas system), ensuring steady output and low energy use. Also, our systems are key for Dynamic Ice Storage solutions, helping facilities manage energy loads, cut peak electricity demand, and greatly lower running costs.

FAQs About Industrial Plate Ice Machines

Q1: What is plate ice, and how is it different from tube or cube ice?

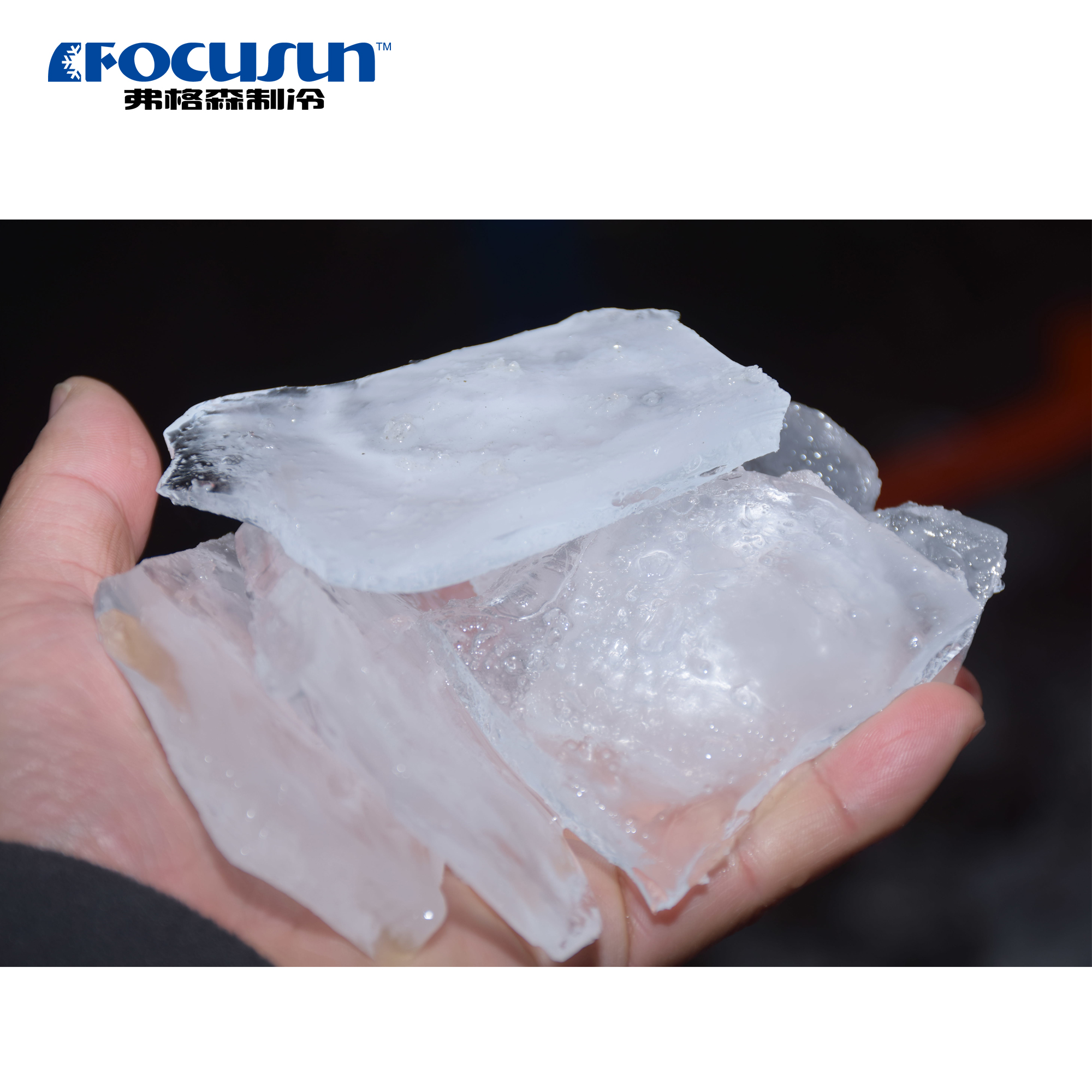

A1: Plate ice is made in thin, irregular sheets or plates on a vertical evaporator surface. They often be broken into smaller flakes or pieces. It has a big surface area, making it great for fast, direct-contact cooling in industrial processes. Unlike the slower-melting tube or cube ice used in drinks, plate ice is made for efficient heat absorption in uses like concrete cooling or bulk seafood preservation.

Q2: What things decide the needed capacity of a plate ice maker?

A2: Main things include your daily ice use (in tons), peak demand times, the specific cooling use (like direct mixing versus ambient cooling), and available space for installation and ice storage. A Focusun expert can do a detailed review to suggest the perfect capacity.

Q3: What maintenance does a plate ice machine need?

A3: Regular maintenance includes cleaning the water system, checking refrigerant levels, and looking at mechanical parts. Focusun gives full guides and support to make sure your industrial ice maker runs reliably with little planned downtime.

Conclusion: Secure Your Production with the Right Ice Solution

Picking the correct plate ice machine is an important step toward stabilizing your core industrial processes, improving product quality, and protecting your profits.

Focusun Refrigeration mixes decades of engineering history with a flexible, client-focused approach. We provide strong, customizable plate ice making solutions that work under pressure, ensuring your cooling chain is a source of strength, not weakness. Contact Focusun today to talk about your specific high-volume cooling challenges. Let our team create a tailored plate ice system that guarantees steady output, operational efficiency, and peace of mind for your business.

Location

Location